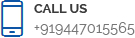

Filter Anthracite Coal

Product Details:

Filter Anthracite Coal Price And Quantity

- 5 Metric Ton

- 1250.00 - 3000.00 USD ($)/Metric Ton

Filter Anthracite Coal Trade Information

- Tuticorin/ Cochin

- 1000 Metric Ton Per Month

- 15 Days

Product Description

We are an eminent manufacturer, exporter and supplier of Anthracite Coal. The offered coal is considered as the suitable filtering option for drinking water, waste water, river water, swimming pool water, ground water, mineral water, spring water and well water. Our Anthracite Coal is widely used in chemical industry, pharmaceutical industry, petroleum refineries, paper mills, sugar refinery and cement factories for its good filtration quality, high purity level and abrasion resistance nature. The salient features of this coal are its ability to safeguard Iron Exchangers, RO Plants and Activated Carbon Filters; high backwash velocity; unique density; low wash water consumption rate; international quality; acid and temperature resistance capacity. The necessary specifications of our coal product include "

Technical Data Sheet of Anthracite Coal

Chemical analysis

- Carbon: approx. 92 %

- Moisture: approx. 2.0 %

- Ash: approx. 3.5 %

- Volatile matter: approx. 5.5 %

- Acid Solubility (19% HCL) 0.5%

Physical parameters

- Bulk density: approx. 730 kg/m

- Bulk Volume 1.37 m3 per ton

- Density: 1.40 1.45 g/cm

- Porosity: < 10 %

- Hardness: approx. 4 Mohs

- Hardgrove: 32 34 HGI

- Attrition Loss per 100 backwash : 0.05%

- Color - Black

Standard grain sizes

- Type I: 0,8 1,6 mm

- Type II: 1,4 2,5 mm

- Type III: 2,0 4,0 mm

- Type IV: 3,5 7,0 mm

When compared with anthracite from Pennsylvania or other places our product is lighter and better in quality as a filter media Pl see chart below.

Our product | Other Anthracite Products |

|

| Bulk Density | 700kg/m3 | 900kg/m3 |

| Density | 1.45gm/cm2 | 1.65gm/cm2 |

| Volatile Matter | <3.5% | >6% |

Other Products in 'Anthracite Coal' category

|

SOUTHERN CARBON & CHEMICAL

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese